Source£ºAnhui Tongcheng New Energy Materials Co., Ltd

Source£ºAnhui Tongcheng New Energy Materials Co., Ltd

Time£º2023.04.15

Time£º2023.04.15

The cost of photovoltaic power generation is an important factor restricting the wider application of photovoltaic products. On the component side, there are two main ways to reduce costs: one is to increase the photoelectric conversion efficiency of photovoltaic products, and the other is to reduce the production cost of photovoltaic products. However, many technologies increase production costs while increasing photoelectric conversion efficiency, until the emergence of multi gate technology, which simultaneously reduces silver paste consumption and improves component power. Since the beginning of this year, photovoltaic companies such as Trina Solar, Longi, Ates, Jinko Energy, and GCL have successively developed 12 main gate module products, and the multi main gate technology has attracted high attention in the industry.

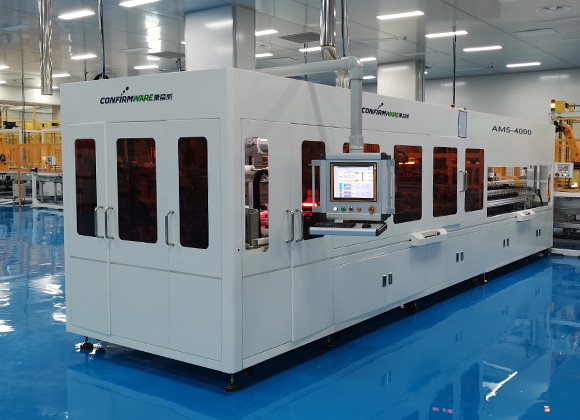

Three years ago, during the subsequent technology roadmap planning, Pioneer conducted multiple investigations and identified half piece and multi main gate MBB as the main development technology routes. The development of half piece equipment was relatively simple, but MBB had very little experience to learn from both domestically and internationally. Foreign developed equipment implemented a technical blockade on China. Starting from scratch, through strategic cooperation with Trina Solar, we have successfully overcome various technical difficulties such as MBB multi grid welding strip alignment and alignment accuracy, welding temperature uniformity and stability, and achieved mass production in a 500MW production capacity workshop in China.

The leading LDTH2000 multi grid (MBB) series welding machine has achieved a mass production capacity of 2000 pieces/hour for infrared welding of multi grid battery cells in China. It can adapt to welding multi grid battery cells below 15 grids and has more than 20 patented technical support. Following the LDTH2000 multi grid welding machine, Pioneer will launch the LDTH2400 multi grid welding machine, which will achieve a mass production capacity of 2400 pieces/hour while ensuring the welding process.

Technical advantages

1. Can provide turnkey technical services for the entire process

2. Innovative integration of busbar welding technology on string welding machines

3. High compatibility: 4BB~15BB have compatibility

4. Alignment accuracy: ¡À 0.2mm

5. High quality welding quality: average welding tension ¡Ý 1N

The Tianhe 12 grid component product has entered the mass production stage. As of early October, the component output is 12MW, and the actual string yield rate is greater than 98.5%. This cannot be achieved without the strong support of the LDTH2000 Multi Barrier (MBB) series welding machine developed in collaboration with Pioneer Intelligence and Trina Solar.

Optional "turnkey" value-added services

Wang Yanqing, Chairman of Pioneer Intelligence, stated that for many years, Pioneer has maintained a technological advantage among domestic photovoltaic equipment manufacturers. In the case of multi grid string welding machines, although foreign equipment was developed earlier, its production capacity and welding quality were poor, and the price was expensive. However, there is no experience in developing such equipment domestically. Pioneer started from scratch and invested a large amount of funds in the research and development of new equipment. From the mass production situation of Tianhe, our product has achieved success. It can be foreseen that the strong alliance between Trina Solar and Pioneer will lead MBB to become a leader in various component technology routes.

Adhering to the concept of "innovation driven" and taking the lead in the original development and manufacturing of photovoltaic cell module automation equipment, we continuously innovate and develop, leading photovoltaic automation equipment towards a faster, more efficient, and more intelligent path.

Previous£ºThere is no previous record

Next£ºThe impact and common specifications of technology dry photovoltaic ribbon on modules!

Return

Copyright 2023 Anhui Tongcheng New Energy Materials Co., Ltd Copyright. ÍîICP±¸2023007224ºÅ